YEAH. WE'RE SERIOUS.

HORL2 Pro is the masterwork of Otmar and Timo Horl. Made of aluminum and stainless steel, the planetary gearing inside provides a transmission ratio of 1:3. Compared to our other HORL2 models, it effectively achieves the desired sharpness three times as fast. With high-quality stainless steel and aluminum components as well as the dark bronze powder coating give this premium knife sharpener an elegant look and at the same time a unique feel.

THE MASTERPIECE

-

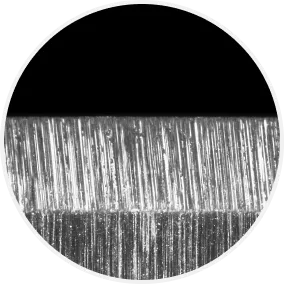

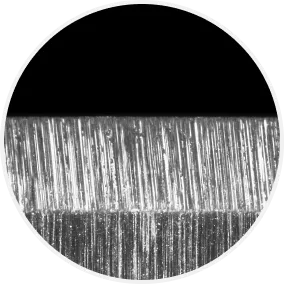

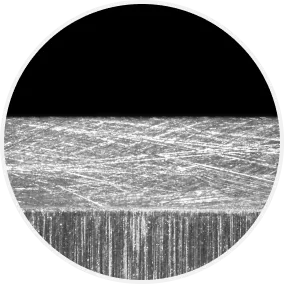

MICROGRAPH OF EX-WORKS

The basis for comparison by microscope is the ex-works grind of a standard high-quality kitchen knife.

-

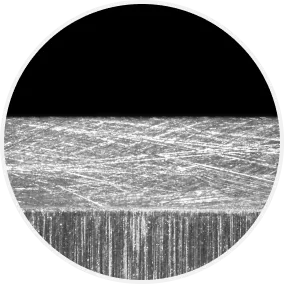

MICROGRAPH AFTER HORL2 Pro

Corresponds to the grinding result from using the HORL2 Pro.

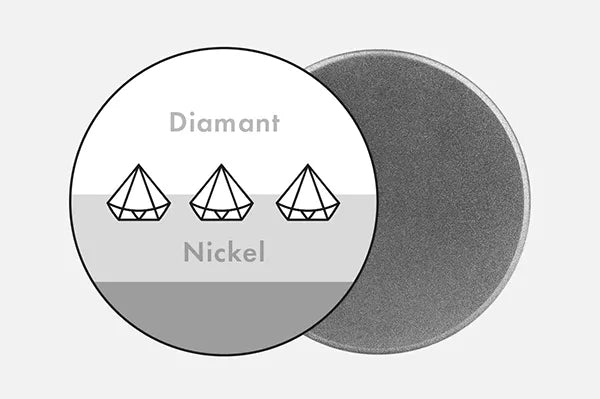

DIAMOND GRINDING DISC

With the HORL standard diamond grinding disc, a high-quality sharpening result is quickly possible without the use of water. The industrial diamonds in the disc are suitable for steels of any hardness used for knives and ensure efficient, precise results. In addition, they produce a grinding pattern that is equivalent to the "ex works" grind of a high-quality German kitchen knife.

CERAMIC HORNING DISC

After use of the HORL diamond grinding disc, the ceramic honing disc further refines the grinding result! Its integrated grooves ensure a smooth knife edge and eliminate any loose metal particles that remain.

20° GRINDING ANGLE FOR ROBUST SHARPNESS

The 20° grinding angle provides new sharpness and a robust cutting edge in a short time. This means the knife retains its sharpness for a long time and is suitable for a wide variety of everyday uses in the kitchen. It also gives many outdoor pocket knives a sturdy edge and excellent sharpness for everyday use.

15° GRINDING ANGLE FOR FILIGREE SHARPNESS

With the 15° grinding angle, particularly fine blades made of Damascus or high-quality carbon steel can be given filigree sharpness. Such knives can be sharpened very finely and they retain their stability.

EFFICIENCY WITH STYLE

Industrial diamonds are considered one of the most durable and efficient abrasives available. The monocrystalline diamonds we use are harder than any knife steel. In an electroplating process around 55 % of the diamonds in the HORL Diamond Standard are firmly embedded on a nickel plate. Their surface, which is rough to begin, is refined during the first grinding procedure and it retains this condition from then on.

HORL S-PAD FOR NON-SLIP VERSATILITY WHILE GRINDING

The combination of strong neodymium magnets and the HORL silicone S-Pad ensures the blade is securely held by the magnetic angle support. Due to the anti-slip properties of the S-Pad, even narrow blades can be sharpened consistently and reproducibly at the required height.

ONE SOLUTION. WIDE VARIETY.

SET INCLUDES

-

HORL2 Pro

-

HORL2 Pro Magnetic Angle Support

-

HORL2 Pro Original Box

THE HORL2 FAMILY WHICH SUITS YOU?

Simply robust sharpness, complete versatility or rapid sharpening? The three sharpeners in the HORL2 family offer the right choice to satisfy every knife sharpening desire.

-

HORL®2 Nut

Regular price $269.00 AUDRegular price -

HORL®2 Pro

Regular price $599.00 AUDRegular price -

HORL®2 Oak

Regular price $269.00 AUDRegular price

Answers to the most frequently asked questions.

Questions? Answers.

1. How do I sharpen knives that are higher than the sharpener?

To grind particularly broad blades, where the cutting edge stands higher than the grinding disc, elevate the sharpener with a suitably thick cutting board to ensure contact with the cutting edge is within the radius of the diamond grinding disc.

2. How can I clean the diamond and ceramic discs?

To remove grinding residue of the diamond and ceramic discs, cleaning with a pencil eraser is sufficient. If necessary, the diamond grinding disc can be unscrewed and thoroughly washed in warm water, with a little washing-up liquid and a brush.

3. How can I change the grinding discs?

Enclose the HORL sharpener firmly with one hand. With the other hand, the desired grinding disc is turned up in an opposite movement. After changing, the grinding discs should again be mounted on the sharpener with the screws tightly screwed down by hand. The grinding discs can be changed on the model HORL2, HORL2 Pro and the first generation HORL sharpeners.